Packaging materials

We produce packaging using a range of materials: paper, folding box-board and corrugated packaging.

Our expert team will suggest a suitable material for your project.

Material selection.

As a packaging specialist we source board from multiple mills and merchants; in stock sizes and in special making sizes based on your project.

- Folding Boxboard - Describes packaging board that is greater than 300 micron in thickness.

- Corrugated Board - Describes board that is made up of 3 layers with a middle wavy fluted layer, giving extra cushioning, rigidity and strength.

Folding boxboard.

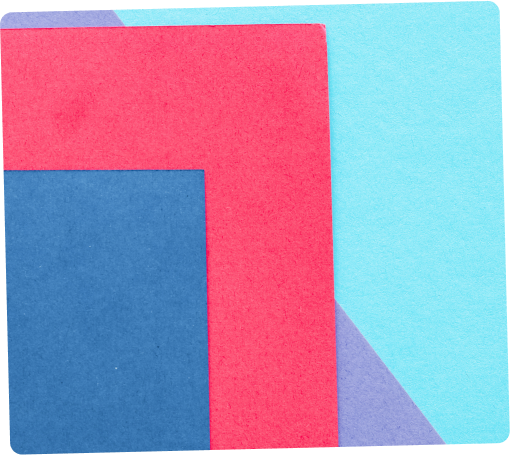

Also known as Paperboard or Carton-board, available in a range of thicknesses and grades as:

- White board - Available with a coated or uncoated surface.

- Coloured board - Colourful uncoated boards for a unique look & feel.

- Mirror boards - Premium shiny metallic look to packaging.

Sustainable: All board is easily recyclable and sourced sustainably with FSC or PEFC accreditations.

Corrugated boxboard.

Micro-flute boards can be printed directly and boards E,F & B flute use a litho-lamination process to print on corrugated boards.

This gives the benefits of a lightweight material with extra cushioning, rigidity and strength. Plus the high print quality of a litho print process.

Sustainable: All board is easily recyclable and sourced sustainably with FSC or PEFC accreditations.

Speciality boards.

We can source specialist board, as required for all kinds of applications.

- Food Grade - Board is manufactured and stored in a high hygiene environment to ensure its suitability for direct contact with food.

- Freezer Grade - Specially treated for moisture resistance required for use in freezers.

- Grease Resistant - Specially treated for grease resistance.

Recycled vs. recyclable.

All board is easily recyclable and biodegradable.

Folding boxboards are almost exclusively available as virgin fibre board.

Only very limited options are available as recycled packaging boards; the strength and rigidity needed for packaging means long virgin fibres are required.

To demonstrate your packaging board comes from sustainable sources. We can add the appropriate FSC or PEFC logo to your packaging design.

The most common grades of board we use:

- 1 sided board GC1 - white back folding boxboard Offers a great printed surface 1 side and a white reverse that can also be printed with a more uncoated texture.

- 1 sided board GC2 - cream back folding boxboard Offers a great printed surface 1 side and a cream reverse with a more uncoated texture

- 2 sided board SBS - double sided board Offers a great printed surface 1 side and a cream reverse with a more uncoated texture.

- Food grade board - many widely available boards are suitable for direct contact with food.

- Freezer grade board - board that is suitable for use in the freezer

Grease resistant board - board that is grease resistant for food packaging. - Kraft board - brown board that is suitable for printing. As standard this has one smooth side and one uncoated side.

- Mirror board - a board that has been laminated with a silver, gold or other metallic surface suitable for printing.

Corrugated boards:

- Micro flute board - N flute is a micro flute board allows for extra rigidity and due to its thickness of less than 1mm it can still be litho printed to directly

- E-flute litho laminated board - A litho printed sheet is laminated onto with an E-flute to give a thicker (1.5mm - 2mm) and more rigid board to cut and crease.

- B-flute litho laminated board - A litho printed sheet is laminated onto with an B-flute to give a thicker (2.5mm - 3.5mm) and more rigid board to cut and crease.